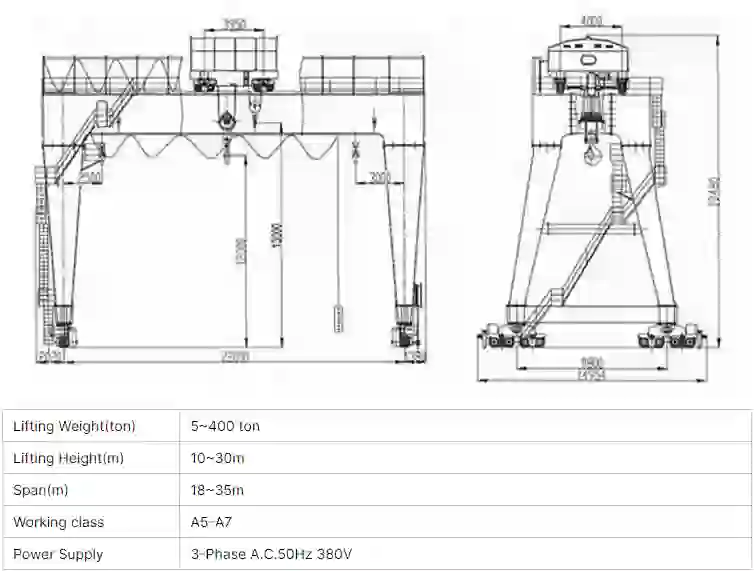

When it comes to Gantry Crane Equipment and Gantry Equipment, The Gantry Crane, particularly double girder variants, consists of crane span structure, crane travel mechanism, trolley and electrical equipment. The crane span structure adopts the box type double girder welding structure while the crane travel mechanism adopts the separate drive, with all the mechanisms operated in the operating housing. All the safety precautions like wind alarm, broken shaft, rollover protection and others are all in readiness.

The main welding is submerged arc automatic welding, nondestructive flaw detection. This crane is widely applied to do loading and unloading work in outdoor. Such as material stocks area. cement plant, granite industry, construction industry, and engineering industry and so on. Besides, Weight overload protection device. Top quality long time bearing polyurethane materials buffer, Crane traveling limit switch, Voltage lower protection function, Emergency stop system, current overload protection system etc. all these insured the crane safety.

The closed cab is employed for operation, where there are adjustable seat, insulating mat on the floor, toughened glass for the window, fore extinguisher, electric fan and auxiliary equipment such as air conditioner, acoustic alarm and interphone which can be furnished as required by users.

The Double Girder Gantry Crane is highly versatile and widely used for outdoor loading and unloading. In material stock areas, it efficiently manages large - scale material handling, stacking and retrieving items with ease. Cement plants depend on it to transfer heavy cement bags and raw materials between production areas. In the granite industry, it's crucial for moving massive granite blocks for further processing. Construction and engineering sectors also rely on this crane. It moves steel beams and pre - fabricated parts, streamlining projects, boosting efficiency, and minimizing manual labor.